What is Powder Processing?

Powder processing transforms raw materials like minerals, ores, ceramics, polymers, and chemicals into ultra-fine particles. The final particle size can be as small as 10 microns or less. Ball mill media, such as alumina or zirconia balls, grind and blend the powders. This process finds applications in the pharmaceuticals, ceramics, chemicals, and metallurgy industries. It enables efficient size reduction, mixing, and homogenization of materials, improving product quality and performance.

Powder Processing with Ball Mill Media Applications

Using ball mill media, powder processing produces fine drug powders, ensuring uniformity and optimal dissolution rates. It enables the preparation of high-quality ceramic powders for shaping and firing processes in ceramics. Chemical industries benefit from powder processing by achieving precise particle size control for catalysts and pigments. Additionally, metallurgical applications involve refining metal powders for additive manufacturing and sintering.

Overall, powder processing with ball mill media is crucial to diverse industries, optimizing product quality and performance. You may find this Introduction to High-Energy Ball Mill useful; or, for more information about milling media written by our MSE Supplies technical staff, please read our article here.

Benefits of Powder Processing with Ball Mill Media

Powder processing with ball mill media offers numerous benefits:

- Fine Powder Production: Powder processing produces 10 microns or fewer particle sizes, creating ultra-fine powders.

- Enclosed Milling for Toxic Materials: This method provides a safe solution for milling toxic materials due to its enclosed form, minimizing exposure risks.

- Versatility: The benefits of powder processing extend to many applications across many industries.

- Continuous Operation: The ball mill supports continuous operation, allowing for efficient and uninterrupted production.

- Milling Abrasive Materials: Powder processing is suitable for milling abrasive materials, ensuring effective size reduction while preserving the integrity of the mill.

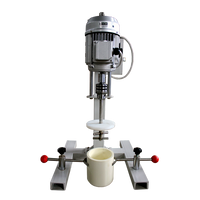

Order Powder Processing Ball Mill Media from MSE Supplies

Nothing less than professional grade milling equipment is sold at MSE Supplies. We carry a wide variety of options for both planetary and roller mills machine equipment. Our materials and supplies for powder processing and mill grinding come with a guarantee for preciseness and quality for your research and development needs. We strive to provide our customers with many options for their mill grinding and powder processing projects and offer our expert services to answer any questions our customers may have. Request a quote or place your order today. Please contact us online with any questions or call (520) 789-6673.