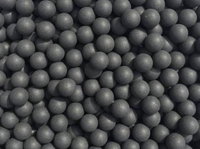

Milling Balls, Grinding Media and Grinding Balls Applications

Planetary milling jars and planetary mill machines frequently utilize milling balls, grinding media, and grinding balls. MSE Supplies provides efficient milling media for various applications, which include:

- Advanced ceramics

- Biotechnologies (DNA & RNA isolation)

- Chemicals, including agrochemicals such as fungicides, insecticides

- Coatings, paints, printing and inkjet printer inks

- Electronic materials and components such as CMP slurry, ceramic capacitors, conductive inks

- Food processing

- Lithium-ion battery materials

- Nanomaterials

- Mineral processing

- Organic synthesis

- Pigments and dyes

- Pharmaceuticals

How to Choose Grinding Media and Milling Media?

It's important to select milling media that will provide the desired results and is compatible with the substance that needs milling or grinding. When selecting milling balls and grinding media, the key properties to consider are:

- Density: Milling media with higher densities yields finer particle sizes. To achieve this, the media's gravity should be higher than the milled substance.

- Particle sizes: The substance you'll be milling can indicate the ideal media's particle size. Large milling media reduce particles quicker while smaller media grinds finer, providing consistent results.

- Hardness: Harder grinding media can be the best solution for more efficient milling and grinding with less contamination and wear.

- Composition: The choice of ball composition and grinding media must align with the material that will be milled for optimal results and to prevent contamination.

- Cost: More expensive options can provide superior grinding with less contamination and wear, making cost a deciding factor when considering milling media prices.

Order Milling Balls, Grinding Media and Grinding Balls From MSE Supplies

MSE Supplies provides quality, durable, and high-performance milling media. Milling balls made of steel and ceramic are our most popular materials. If you have questions regarding MSE Supplies milling media, please request a quote, contact us online, or call us at (520)789-6673 today. Our in-house experts are ready to help you select the best milling balls and media for your needs.