100 mm JGS1 Ultraviolet (UV) Grade Fused Silica Wafer, 500 um, DSP, w/ Bevel, Primary Flat Only

SKU: WA1002

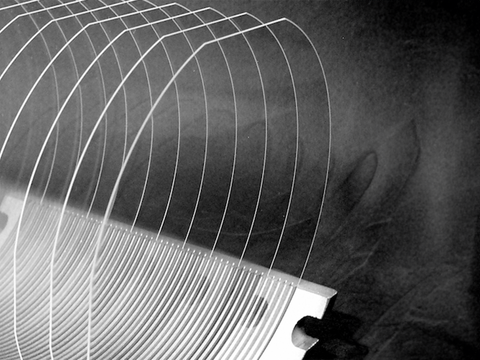

100 mm JGS1 Ultraviolet (UV) Grade Fused Silica Wafer, 500 um, DSP, w/ Bevel, Primary Flat Only

The JGS1 Ultraviolet (UV) Grade Fused Silica is free of bubbles and inclusions, transparent in the ultraviolet and visible regions, and has no absorption band between 170 and 250 nm. UV grade Fused Silica (JGS1) is synthetic amorphous silicon dioxide of extremely high purity. It exhibits a broad OH absorption band between 2600 and 2800 nm.

JGS1 Ultraviolet Grade Fused Silica is comparable to Suprasil 1 and 2 (Heraeus), Spectrosil A and B (Saint-Gobain) and Corning 7940 (Corning), Dynasil 1100 and 4100 (Dynasil).

Fused silica is used for both transmissive and reflective optics, especially where high laser damage threshold is required. JGS1 is used for optics operating in the deep UV and the visible wavelength range (Laser Lenses, Windows, Prisms, Mirrors, etc.).

Order 100mm JGS1 Ultraviolet Grade Fused Silica wafers with the best price on the market from a trusted materials science supplier, MSE Supplies.

- Custom made JGS fused silica wafers and substrates are available upon request. Please contact us for a quote.

- Corning Fused Silica 7980 High Purity Fused Silica (HPFS) and JGS2 Fused Silica wafers, windows and substrates are also available and can be custom made. Please contact us for a quote.

Product Number: WA1002

Material: SiO2, fused silica (fused quartz)

Grade: JGS1 (UV Grade Fused Silica)

Diameter: 100 +/- 0.2 mm

Thickness: 500 +/- 50 um

Primary Flat: 32.5 +/- 2.0 mm (primary flat only)

Surface Polishing: Double Side Polished (DSP) with surface roughness Ra < 1 nm on both the top surface and bottom surface

Surface Finish: S/D 40/20

TTV: < 10 um

Edge: with Bevel, C shape CNC edge grounding

Physical Properties of Fused Silica

- Density: 2.2 g/cm3

- Coefficient of Thermal Expansion: 5.5*10^-7 /°C (20°C-320°C)

- Thermochromism: Under constant temperature of 1140 degrees, keep annealing for 30 minutes without discoloration.

Fused silica (SiO2) wafers are made from high purity fused silica, ground and polished to optical grade on both sides. The fused silica wafers are suitable for many optical applications because of their excellent optical transmission characteristics. Fused silica also has excellent chemical resistance against a wide variety of solvents, as well as exceptional heat resistance, with high dimensional stability over a wide temperature range thanks to its ultra low thermal expansion coefficient.

Single Crystal Quartz Wafers and Substrates are also available.