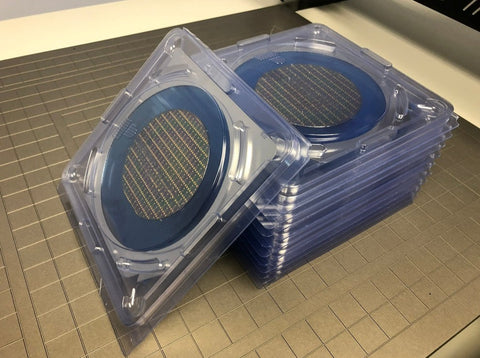

Die cutting is a mechanical process that involves separating individual chips (die) on a substrate, from each other. This process is also known as singulation.

MSE Supplies owns and operates a high-precision mechanical glass cutting machine, equipped with a diamond-finished scribing wheel. The tool produces well-defined scribing lines on the substrate, and after-break edges require no polishing. Unlike laser cutting, this method does not produce heat-induced substrate distortions in silicon.

MSE Supplies also offers laser cutting of flexible substrates with patterned metal films fabricated by our team.

Combined with our high-quality surface cleaning capabilities, our cutting services allow for clean singulation with high edge quality, and high yield.

Upon request from the customer, a protective surface coating can be applied to the wafer or glass to protect sensitive components from dust or other contamination. This protective surface coating can be removed with acetone or ethanol following cutting.

Capabilities

- Repeatable accuracy of +/- 0.002″

- Smallest die: 5mm

- Clean edge quality and high yield

- Rectilinear (x-y) shapes, curvilinear and circular shapes