IEST Battery Slurry Resistivity Analyzer

SKU: IE0401

MSE Supplies offers battery slurry resistivity analyzer for various battery research and mass production. Slurry is an important intermediate product in the production of lithium-ion batteries. Its uniformity and stability have significant effects on the consistency and electrochemical performance of the final battery cell.

Unlike the slurry analyzer on the market (measure viscosity related parameters only) that cannot evaluate the electrical properties accurately, our Battery Slurry Resistivity Analyzer can evaluate various properties. It can evaluate different electrochemical performance of the materials, such as slurry formulation (viscosity, dilution), conductive agent type, dispersant type and content, gel sedimentation (dwelling time), and many other properties. These properties are important in monitoring the production of slurry as the conductivity value will show varying degrees of change. Therefore, the conductivity of the slurry can be used as a method to characterize the uniformity and stability of the electrical properties of the slurry. It can be used for monitoring the process stability by identifying the abnormalities in time and avoid the waste of time and cost caused by the defective products.

Slurry Resistivity Test Principle:

Test steps:

a. Putting a certain volume of slurry (~80mL) into the measuring glass

b. Inserting a clean electrode pen and start the software

c. Start to test the changes in the slurry resistivity of the three pairs of electrodes over time and save it in the file

Test parameters: Resistivity, Temperature, Time

Calculation formula: Resistivity (Ω·cm): ρE = U/I * S/l

Characterization:

1. Separate the voltage and current lines, eliminate the influence of inductance on voltage measurement, and improve the accuracy of resistivity detection

2. A disk electrode with a diameter of 10mm ensures large contact area with the sample and reduces the test error

3. Monitoring real-time changes in resistivity of the slurry at three positions in the vertical direction

Slurry Resistivity Analyzer MSA:

Test program: Three operators, 3 times testing for each operator

Test method:

a. Deionized water was sonicated for 30 seconds

b. Cleaned with deionized water,

c. Dried with dust-free paper

d. 5 sets of data were tested, and the fifth set of data was taken for Gage Repeatability and Reproducibility (GRR) analysis.

Applications:

-

Material Evaluations: dispersant type, conductive agent type

-

Formulate Evaluations: viscosity, dilution

- Gel Sedimentation Evaluations: dwelling time

Technical Specifications:

| SKU | IE0401 |

| Dimension, W×D×H (mm) | 210*300*120 |

| Resistivity Measurement Range (Ω·cm) | 2.5~50M |

| Resistivity Measurement Resolution (μS/cm) | 0.01 |

| Resistivity Measurement Accuracy (%) | ± 0.5 |

| Supply Voltage (V) | 110V |

| Supply Power (W) | < 80 |

| Environmental Temperature (°C) | 0 ~ 40 |

| Weight (kg) | 5 |

Examples:

1. Evaluations of different viscosity in slurry resistivity

The resistivity being lower and conductivity being better with the viscosity of slurry increasing. We can formulate specifications for the resistivity of a certain fixed viscosity of the slurry to monitor the stability of the slurry mixing process.

2. Evaluations of different dilution multiples in slurry resistivity

The resistivity increasing and conductivity being worse with the viscosity of the dilution times of slurry decreasing. We can formulate specifications for the resistivity of a certain dilution multiples of the slurry resistance to monitor the stability of the slurry mixing process.

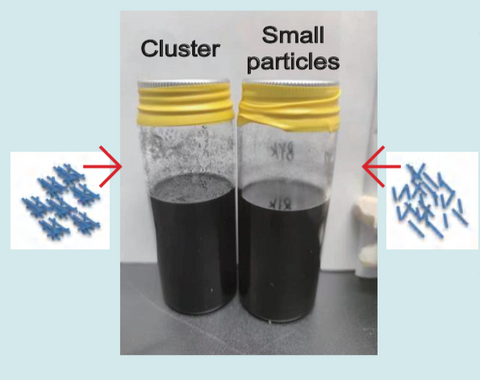

3. Evaluations of different dispersant in slurry resistivity

Different dispersants added to the conductive carbon slurry affects the dispersion shape of the conductive carbon. The resistivity of the conductive carbon slurry in cluster dispersion is lower than the small particle dispersion. We can formulate specifications for the resistivity of a certain dispersant of the slurry to monitor the stability of the slurry mixing process.

4. Gel sedimentation evaluations: Comparing different types of conductive agent

For Slurry-A, on the third day morning, the resistivity of the lower channel electrode was significantly lower than the middle channel and the upper channel, which indicates that the slurry had settled (most of the particles settled to the bottom). The electrical conductivity becomes better as the resistivity decreases.

For Slurry-B, the resistivity only changed slightly, which indicates that there was no obvious settlement. A standing period can be set for the slurry resistivity of a certain fixed type of conductive agent to ensure the uniformity of the slurry.