Customized Silicon Carbide Engineering Ceramic Components

SKU: JA1000

To better serve you, we would like to discuss your specific requirement.

Please Contact Us for a quote.

MSE Supplies offers customized silicon carbide (SiC) engineering ceramic components to meet our customers' application requirements.

The self-bonding fine-grained microstructure of our MSE PRO engineered SiC ceramics have superior properties:

- High strength, high density, hardness close to diamond, wear resistant.

- Excellent chemical stability, resistant to corrosion of various acids, alkalis, and organic solvents.

- High thermal conductivity, low thermal expansion coefficient, thermal shock resistance, and minimum thermal deformation.

- High temperature resistance above 1600 degree Celsius, with excellent oxidation resistance.

- The resistivity is 106-108Ω, non-magnetic, and meets the requirements of ESD resistance specifications.

- High stiffness and excellent thermal uniformity, low probability to bend or deform after long time use.

- Plasma resistant, especially suitable for etching process in the semiconductor industry.

- Low density and light weight.

Typical Properties and Specifications of MSE PRO Engineered SiC Ceramics:

- SiC Content: >99%

- Average Grain Size: 4-10 microns

- Bulk Density: >3.14 g/cm3

- Apparent Porosity: <0.5%

- Vickers Hardness (HV0.5): >2800 Kg/mm2

- Flexural Strength (modulus of rupture) by 3-point bending at 20C: ~450 MPa

- Compressive Strength at 20C: 3900 MPa

- Modulus of Elasticity: ~420 GPa

- Fracture Toughness: ~3.5 MPa / m1/2

- Thermal Conductivity: 160 W/(m*K)

- Electrical Resistivity: 10^6-10^8 Ohm.cm

- Coefficient of Thermal Expansion, CTE (from RT to 800C): 4.3 x 10^-6 /K

- Max. Use Temperature in Air: 1700 deg. Celsius

Industries and Applications We Serve

Aerospace & Defense | Automotive & Transportation | Chemicals and Pharmaceuticals | Electronics | Energy | Equipment & Machinery | Glass | Lighting | Lithium Battery Materials | Medical | Semiconductor | Solar | Technical Ceramics

For Research Use Only (RUO). Not for use in diagnostic procedures.

Examples of Products

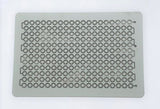

Silicon Carbide Vacuum Chuck and Wafer Handling Arm

Silicon Carbide Vacuum Chuck and Wafer Handling Arm is formed by isostatic pressing process and high temperature sintering. The external dimensions, thickness and shapes can be finished according to the user's design drawings to meet the user's specific requirements.