Battery Electrode Resistivity Analyzer

SKU: SOINS014

To better serve you, we would like to discuss your specific requirement.

Please Contact Us for a quote.

MSE Supplies offers the Battery Electrode Resistivity Analyzer for various battery research and mass production applications. Our system allows the users to measure the electrode resistance in effective and revolutionary ways. By using the information from the electrode resistance, the formulation of composite electrodes as well as the control parameters of mixing, coating and calendaring processes can be optimized.

Importance of Electrode Resistance (Conductivity):

Electrode resistance (conductivity) is significant in the battery manufacturing industry. It influences the basic performance of batteries (power capability, reliability, safety, etc.) By measuring the electrode resistance and other related properties of electric conductive (such as micro structural uniformity of electrodes), we can evaluate the manufacture process in advance.

In the composite electrodes, the electric conductivity is determined by several primary factors (interfacial resistance between the coating layer and the conductive foil, distributions of conductive agents, intrinsic resistance of active material, contact areas between particles, etc.).

Our Unique Testing Process:

1. Comprehensively assessment of the slurry stability from the stirring, coating to the calendering process, which helps to recognize the anomaly aggregation of conductive agents in advance

2. Recognition of uneven mixing on mixture silicon carbon cathode

3. Assessment of electric conductivity of formulas for different active materials

4. Assessment of electric conductivity of formulas for different conductive agents

5. Assessment of electric conductivity of the functional precoating lays of current collector

6. Failure analysis for the electric conductive network failure of batteries

7. Analysis of contact resistance of the positive or negative electrode surface after formation

Technical Specifications:

| Dimension, W×D×H (mm) | 355*320*800 |

| Resistance Range (Ω) | 1μ ~ 3.1k |

| Resistance Accuracy | ± 0.5%F.S |

| Pressure Range (MPa) | 5~60 |

| Pressure Accuracy | ± 0.3%F.S |

| Thickness Range (mm) | 0 ~ 5 |

| Thickness Accuracy (um) | 0.1 |

| Thickness Resolution (um) | ± 1 |

| Temperature Range (°C) | 0 ~ 50 |

| Humidity Range | 20 ~ 90%RH |

| Temperature Accuracy (°C) | ± 2 |

| Humidity Accuracy | ± 5%RH |

| Supply Voltage (V) | 220 |

| Power Dissipation (W) | 450 |

| Environmental Temperature (°C) | 20~30 |

| Environmental Humidity at 40°C | < 80%RH |

| Environmental Magnetic Field | Keep away from intense electromagnetic |

| Weight (kg) | 85 |

Examples:

1. Correlation between powder conductivity and electrode conductivity

By adjusting the Ni content in the NCM material and testing the powder conductivity, we can see that as the Ni content increases, the powder conductivity increases.

Also, by comparing three NCM pieces with different Ni content, we can see that as Ni content increases, the conductivity of the electrode piece increases.

2. Evaluate the resistivity of uncalendered electrode pieces under different compaction densities

- Graphite Electrode: We can see that as the compaction density increases, the resistivity continues to decrease. It is because the contact between active materials increases and the overall conductivity of the electrode becomes better.

- NCM Electrode: We can see that as the compaction density increases, the resistivity of the pole piece continues to decrease. It is because as the pressure increases, the contact between terminals and the active material becomes better.

3. Evaluation of electrode primer technology

From above graphs, we can conclude the followings.

a) The thicker the primer, the greater the resistance of the current collector.

b) The thicker the primer, the greater the cathode resistance.

c) Based on the correlation graphs, we can determine the best primer coating process. The electrode resistance test can be used as a method for long-term monitoring of process stability.

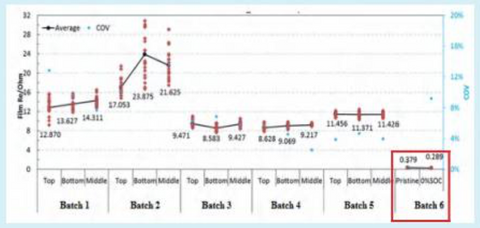

4. Conductive agent distribution uniformity evaluation

By monitoring the change of the resistance of the battery electrode and identifying the abnormal battery electrode, we can prevent the defect battery electrode from flowing into the next process and save the production costs.

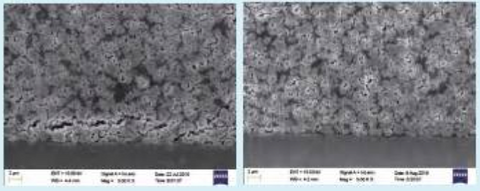

5. Analysis of electrode resistance during high temperature cycle & storage

The resistance of the cathode increases as the number of cycles increases, which indicates that a large change has taken place on the cathode side after the high temperature cycle. The result is likely related to the byproducts on the surface of the cathode particles or the contact between the particles.

The resistance of the anode membrane increases as the storage time extends, which indicates that the anode side changed a lot during the storage process. The result is likely related to the increase of side reactions on the anode material surface.

Models

| IE0101 | IE0102 | IE0103 | IE0104 | |

| Press mode | Cylinder(Pipeline gas required, range:5~35Mpa) |

Servo motot (No pipline gas required, range: 5~60 MPa) |

||

| Parameters | Resistance, Pressure, Temperature and humidity | Resistance, pressure, temperature, humidity, conductivity and resistivity | Resistance, pressure, temperature, humidity, conductivity and resistivity | Resistance, pressure, temperature, humidity, conductivity , resistivity, thickness and compaction density |

| Function |

One point test constant pressure condition |

Included IE0101 function Automatic measurement software |

Included IE0102 function Variable pressure |

Included IE0103 function Thickness measurement Compaction density measurement |