Microfluidic Coriolis Flow sensor ELV-003

- Working range 1 g/h to 2000g/h

- 0.2% accuracy

- Large liquids and gas compatibility

- Compatible with OB1, AF1 instruments

- Adapters Face-seal male 1/4"

- Comes with Swagelok fittings.

- Elveflow® Smart Interface software included.

Specifically designed to suit microfluidic requirements, this flow rate sensor is based on the Coriolis principle. Its features make it the best and smartest solution for microfluidics applications:

- Extremely wide flow rate range

- High accuracy

- Direct mass flow measurement, independent of fluid properties

- Non-invasive measurement

- Additional density and temperature outputs

- Bi-directional measurement

- Fast response

Flow Rate Control

You can achieve flow control of your experiment by combining the Coriolis Flow Sensor with our pressure controller systems (OB1, COBALT). The Elveflow ESI software automatically adjusts the pressure to reach the required flow rate. Researchers who want to monitor the flow rate from their third party fluid driver can plug the flow sensor directly onto the computer.

- Cost-effective solution: one sensor’s operating range covers the ranges of several standard microfluidic sensors.

- No calibration required

- Stand alone sensor: plug the sensor directly to your computer to measure the flow rate.

- Excellent repeatability and long-term stability

- Excellent accuracy: down to 0.2 % of measured value accuracy

- Easy to install and use

- Low risk of gas bubble inclusion

How Does a Coriolis Flow Meter Work?

A microfluidic Coriolis flow sensor contains a U-shaped loop which constantly vibrates. When a fluid flows through this vibrating loop, Coriolis forces are generated and bend or twist the tube. The extremely small tube displacements are detected by sensors and fed to the electronic board. Since the measured phase shift is proportional to the mass flow, the Coriolis flow rate sensor measures the mass flow directly. This measurement principle is very accurate, fast and, more importantly, independent of the properties of the fluid (density, temperature, viscosity, pressure, heat-capacity or conductivity).

Which Flow Rate Sensor Should You Choose?

Elveflow offers two types of flow rate sensors: one based on thermal conductivity technology (Microfluidic Flow Sensor) and one based on Coriolis principles (Bronkhorst Flow Sensor). Both sensors have pros and cons that we have summarized in the table below. This table helps you choose your sensors depending on your application and your budget.

| Flow Sensors Comparison |

BFS |

MFS |

| Accuracy |

0.2 % of measured (1)

|

0.5 % of measured |

| Range |

One sensor for 1.6 µl/min to 3 mL/min |

Five sensor from 10nL/min to 5 mL/min |

| Negative flow measurement |

Yes |

Yes |

| Supported fluid types |

All without calibration |

All without calibration |

| Response time |

35 ms (2)

|

From 1 to 70 ms (2)

|

| Flow sensor size |

65 x 32 x 144 mm

|

58 x 53 x 23 mm |

| Internal diameter |

250 µm |

From 250 µm to 1.8 mm (4)

|

| Weight |

3 kg |

100 g |

| Connector |

1/16* OD tubing |

1/16* OD tubing |

| Internal volume |

13 µL |

From 1 µL to 80 µL (4)

|

| Wetted material |

Stainless steel 316L or comparable |

Silicium |

| Principal |

Coriolis |

Thermal |

| Computer connection |

Directly via USB to the computer |

Directly on the OB1 and the AF1 or with the Sensor reader MSR |

| Additional features |

Temperature and density measurement |

|

(1) Available upon request. 2 % accuracy for the regular model

(2) 0.2 s at 98% (spec) to fill the tubing then 35 ms with temperature measurement

(3) Depending on chosen digital resolution

(4) Depending of the sensor range

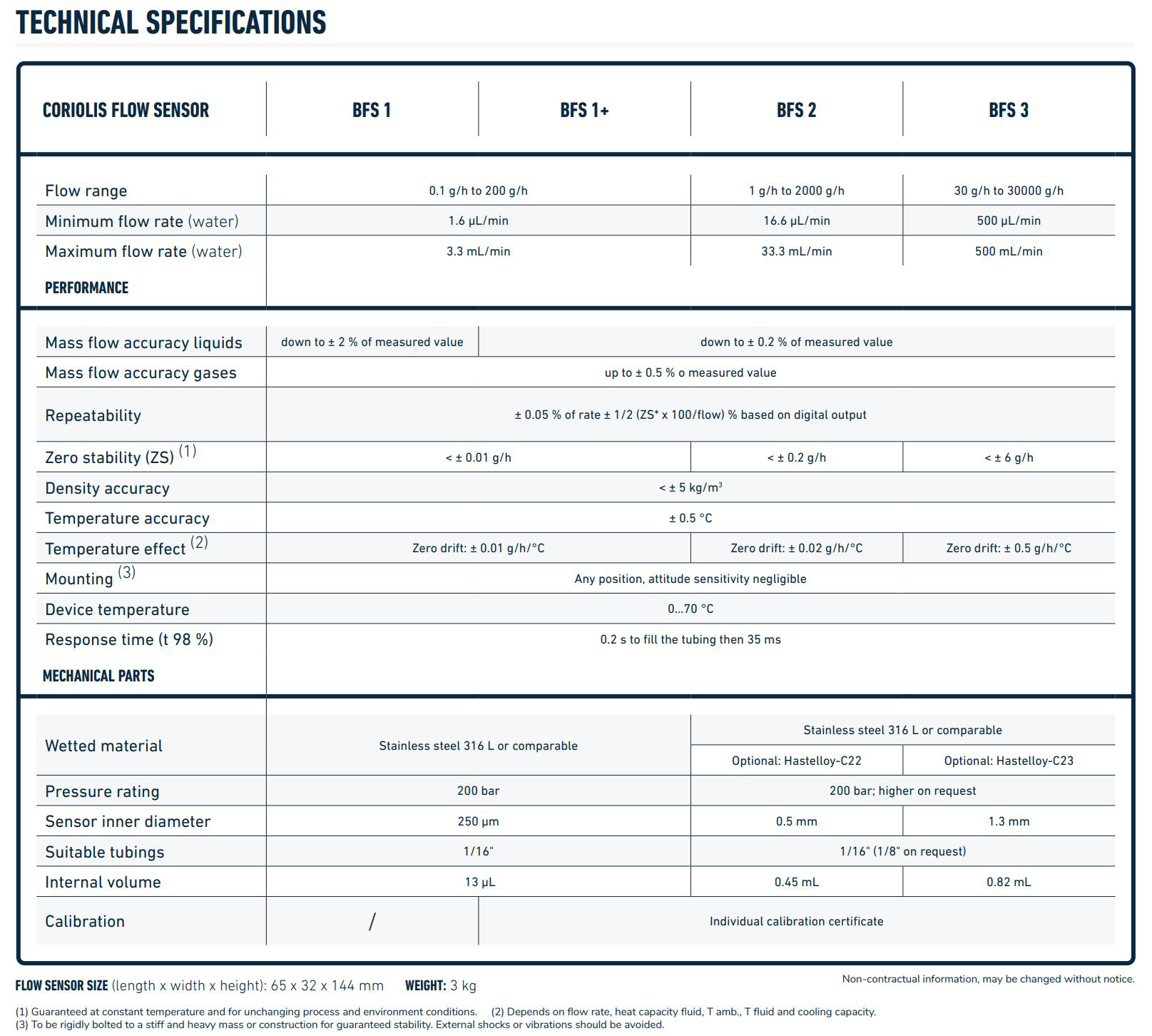

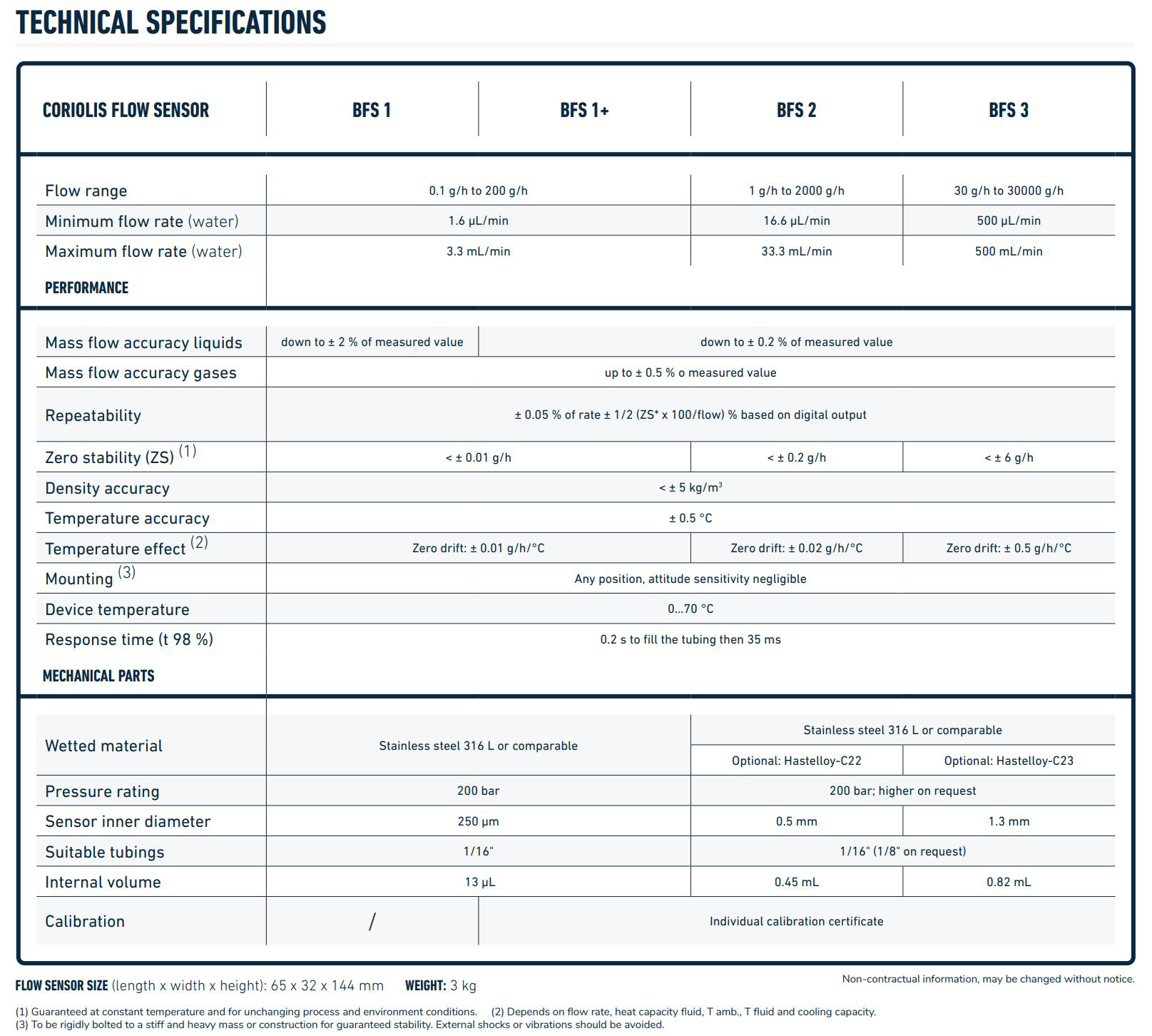

Specifications

Elveflow offers different Premium Coriolis Flow Rate Sensors, which vary by their operating flow rate range. The following table sums up the main features of the different sensors:

(1) Guaranteed at constant temperature and for unchanging process and environment conditions.

(2) Depends on flow rate, heat capacity fluid, T amb., T fluid and cooling capacity.

(3) To be rigidly bolted to a stiff and heavy mass or construction for guaranteed stability. External shocks or vibrations should be avoided.